Mastering Digital Transformation in Manufacturing: Strategies and Benefits

Digital transformation in manufacturing uses digital technologies to enhance efficiency and reduce costs. This article explains key strategies, benefits, and real-world examples while addressing potential challenges.

Key Takeaways

-

Digital transformation in manufacturing optimizes revenue, reduces costs, and enhances productivity through the integration of advanced technologies such as IoT, AI, and machine learning.

-

Key benefits of digital transformation include improved operational efficiency, enhanced quality control, and increased workplace safety, driving significant reductions in downtime and costs.

-

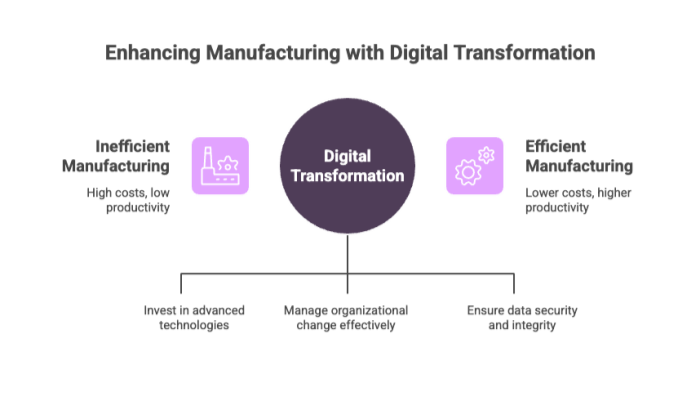

Successful digital transformation requires strategic investment in technology, effective management of change, and robust data management practices to address challenges and ensure security.

Understanding Digital Transformation in Manufacturing

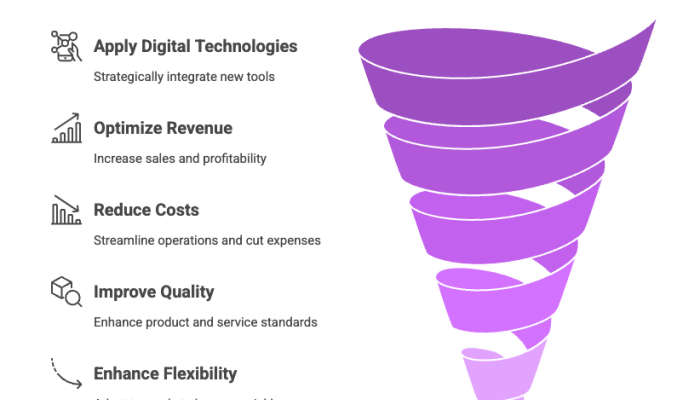

Digital transformation in manufacturing involves strategically applying digital technologies. This aims to optimize revenue, reduce costs, improve quality, and enhance flexibility. Examining discrete manufacturing processes and integrating new technologies can transform product engineering, manufacturing, and servicing. This transformation addresses traditional business challenges and creates disruptive opportunities.

Embracing digital technology resolves outdated processes and enhances overall productivity. The aim is to leverage digital solutions for more efficient and responsive manufacturing processes.

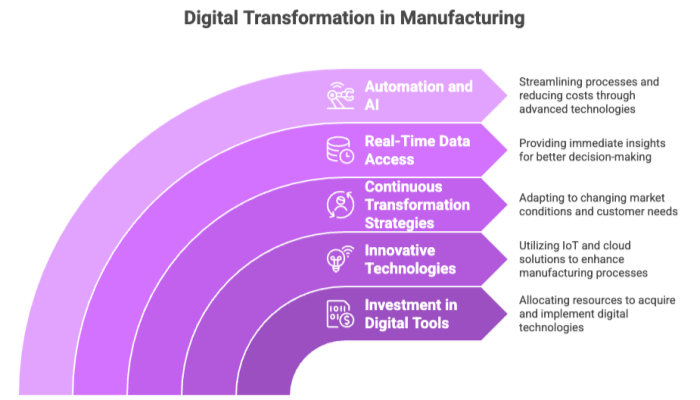

Key Drivers for Digital Transformation in Manufacturing

The rapid evolution of the manufacturing industry requires investment in digital tools to stay competitive. Innovative technologies like IoT and cloud solutions help manufacturers remain viable. Continuous transformation strategies help manufacturers respond effectively to changing customer needs and market conditions.

Real-time access to manufacturing data enhances decision-making and operational efficiency. Automation and AI streamline processes and reduce operational costs, making digital transformation a vital strategy for manufacturers aiming to remain relevant in the evolving landscape.

Major Benefits of Implementing Digital Technologies in Manufacturing

Implementing digital technologies in manufacturing offers numerous benefits, including enhanced operational efficiency, cost reductions, and improved safety and quality. Companies leveraging big data can identify operational trends and make informed strategic decisions.

Digital transformation initiatives have led to significant reductions in machine downtime and have enabled proactive services like preventive maintenance. The integration of advanced technologies drives productivity, reduces costs, and enhances customer engagement, making digital transformation a cornerstone of modern manufacturing strategies.

Enhanced Efficiency and Productivity

Digital transformation enhances efficiency and productivity by streamlining processes. Key digital applications include:

-

Implementing machine learning to optimize production schedules and improve overall manufacturing efficiency.

-

Using AI applications in smart manufacturing to improve forecasting and production planning.

-

Analyzing data from existing tools to establish a foundation for industrial automation and better decision-making.

Smart manufacturing employs advanced manufacturing digital technologies to streamline communication and data collection, resulting in increased overall equipment effectiveness.

Improved Quality Control and Reduced Rework

Digital transformation reducing rework by improving product data management and monitoring software processes. Enhanced data management allows better tracking of production issues, leading to fewer errors in creating products.

The use of increased sensors and automated testing during the production line ensures higher quality products and helps maintain high standards by identifying issues early. These advancements not only improve efficiency but also contribute to cost savings and enhanced customer satisfaction.

Increased Safety and Fewer Workplace Injuries

Digital technologies significantly enhance workplace safety by:

-

Improving processes and guiding workers to perform tasks safely

-

Aiding in training and guiding workers

-

Improving safety standards

-

Automating hazardous tasks to minimize risks and ensure a safer working environment for employees.

The result is a reduction in workplace injuries, contributing to overall operational efficiency and employee well-being, with an added benefit.

Real-World Examples of Digital Transformation in Manufacturing

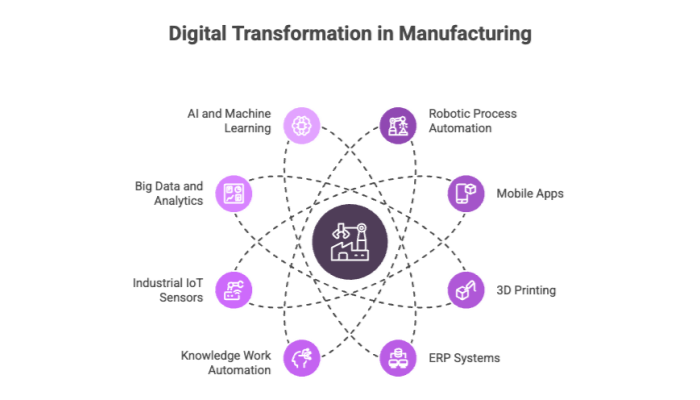

Real-world examples of digital transformation showcase the practical application of digital technologies and their impact on manufacturing. Technologies integral to this transformation include:

-

Robotic process automation

-

Mobile apps

-

3D printing

-

ERP systems

-

Knowledge work automation

The integration of these technologies has enabled manufacturers to streamline operations, enhance flexibility, and respond more rapidly to market changes. These implementations yield significant benefits such as improved efficiency, reduced costs, and enhanced quality control in manufacturing processes, demonstrating the transformative power of digital solutions.

Utilizing Industrial IoT Sensors

Industrial IoT sensors are integral to monitoring production lines, providing critical data for decision-making. These sensors facilitate real-time monitoring of equipment, leading to improved operational decision-making and predictive maintenance. IoT technology can be implemented in various locations, including manufacturing plants, to gather critical data that drives efficiency and productivity in the industrial internet.

Industrial IoT sensors exemplify how digital transformation enhances operational oversight and maintenance practices.

Leveraging Big Data and Analytics

Big data analytics helps manufacturing firms identify operational trends and make data-driven decisions. Analyzing large volumes of data helps manufacturers identify patterns in processes, leading to more effective decision-making and improved efficiency.

Predictive maintenance utilizing big data and predictive analytics is prevalent in industries like automotive and pharmaceuticals, reducing downtime and optimizing production efficiency. Leveraging big data and analytics is a cornerstone of manufacturing digital transformation initiatives.

Integrating AI and Machine Learning

AI and machine learning technologies are increasingly applied for automation and process improvements in manufacturing. These technologies enable manufacturers to automate complex tasks, enhance production planning, and optimize resource allocation. By integrating AI and machine learning, manufacturers can achieve higher levels of efficiency and productivity, setting new standards for operational excellence.

Integrating artificial intelligence and machine learning is a transformative aspect of digital manufacturing strategies.

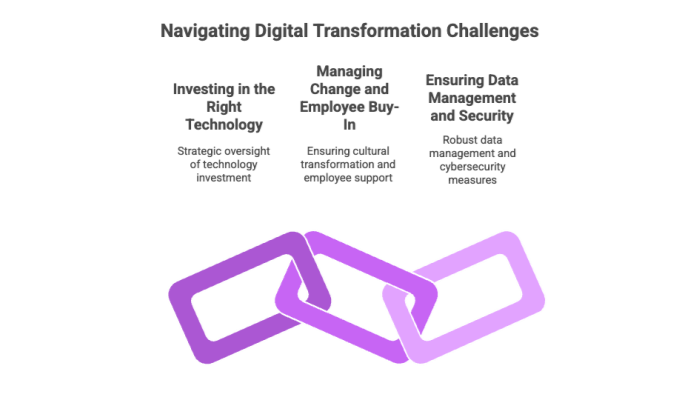

Overcoming Challenges in Digital Transformation

Manufacturers often encounter significant challenges in digital transformation, including many manufacturers dealing with organizational silos, integrating legacy systems, managing multiple digital projects, shortage of skilled labor, and the need to keep pace with rapid market changes.

Overcoming these biggest challenges is essential for successful digital transformation and achieving desired outcomes.

This section will explore strategies to navigate these hurdles and ensure effective implementation of digital technologies.

Investing in the Right Technology

Strategic oversight of technology investment is crucial for successful digital transformation. Choosing partners with a proven company industry history and assessing their reputation and expertise significantly enhances success.

Regular evaluation and updating of digital strategies are crucial for adapting to market changes and maintaining a competitive edge. Investing in the right technology ensures that digital transformation initiatives drive business growth and operational efficiency.

Managing Change and Employee Buy-In

Resistance to cultural change is a major barrier to implementing digital transformation initiatives. Key factors for successful digital manufacturing include:

-

Effectively managing change and ensuring management and staff buy-in

-

Addressing the lack of digital skills and knowledge among employees

-

Providing effective onboarding and training to support new technology adoption

Leadership needs to focus on developing partnerships and leading the organization through cultural transformation to align employee goals with business objectives.

Ensuring Data Management and Security

Robust data management is crucial for digital initiatives, enabling informed decision-making and operational efficiency. Practices must ensure data is accessible, traceable, and hygienic for effective digital transformation.

Increased connectivity in digital manufacturing raises significant cybersecurity risks, making data security a top priority. Ensuring robust data management and security is essential for safeguarding sensitive information and maintaining the integrity of digital transformation efforts.

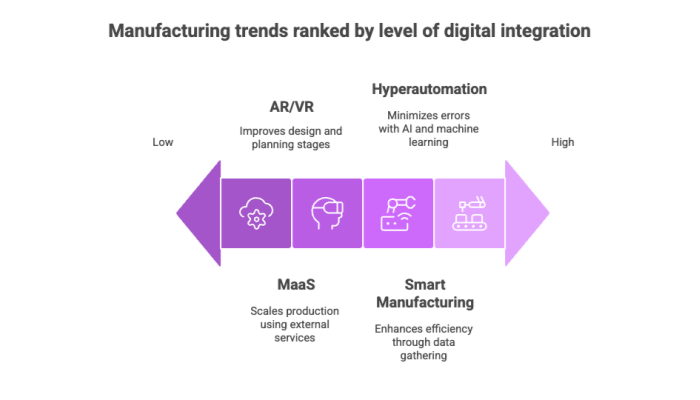

Future Trends in Digital Transformation for Manufacturing

Emerging trends in digital transformation for manufacturing are poised to reshape processes and operational efficiencies. Hyperautomation, which integrates AI and machine learning to minimize human errors, fosters a culture of continuous improvement. Condition monitoring using sensors is projected to become standard practice, enabling real-time oversight of machinery and equipment.

These trends highlight the ongoing evolution of digital transformation in manufacturing, driving innovation and operational excellence.

Advancements in Smart Manufacturing

Smart manufacturing seeks to make processes more efficient and productive through digital technology and automation. Advanced technologies like digital twins and IoT enhance operational efficiency by streamlining communication and data gathering.

Smart manufacturing can enhance different areas such as production management and quality control. It also plays a crucial role in improving supply chain management, resulting in significant advancements in the manufacturing environment.

Growth of Manufacturing-as-a-Service (MaaS)

MaaS enables manufacturing companies to scale production without significant capital investments by utilizing service-based manufacturing models in a manufacturing business. This approach allows manufacturers to leverage external contractor capabilities to efficiently scale production and respond to market demands.

MaaS shifts from traditional manufacturing processes to more flexible and scalable solutions, driving business growth and operational efficiency.

Expansion of Augmented and Virtual Reality Applications

AR and VR technologies significantly improve processes and increase efficiency in manufacturing. Virtual reality creates simulations that allow visualization of the finished product before production, enhancing design and planning stages.

Augmented and virtual reality technologies are increasingly being adopted in the manufacturing sector, driving innovation and improving operational practices.

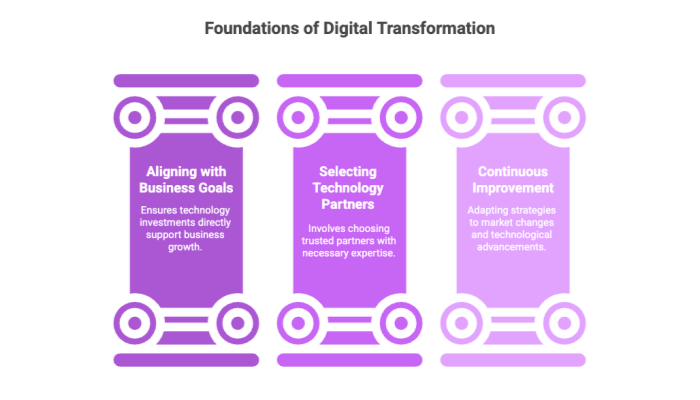

How to Develop a Successful Digital Transformation Strategy?

A successful digital transformation strategy requires clear objectives and metrics to measure progress. Aligning technology investments with organizational goals ensures impactful efforts that support business growth. Promoting a continuous improvement mindset within manufacturing organizations is essential for adapting to market changes and technological advancements.

This section will provide guidelines on developing a robust digital transformation strategy.

Aligning Digital Transformation with Business Goals

Alignment with business goals is essential for the success of a digital transformation strategy. Digital strategies should directly support the overarching business strategy to ensure technology investments are impactful and drive business growth.

Regularly aligning digital transformation efforts with business operations and goals ensures continued progress and operation excellence.

Selecting the Right Technology Partners

Identifying trusted partners with the right technology and expertise is crucial when finding a technology partner for digital transformation in manufacturing. Choosing technology partners involves assessing their trustworthiness and ensuring they offer the necessary expertise for digital transformation.

Selecting the right technology partners ensures that digital transformation initiatives are successful and aligned with business objectives.

Continuous Improvement and Adaptation

Ongoing evaluation of digital strategies ensures they align with market changes and technological advancements. Companies must adapt their strategies to remain competitive in the competitive landscape and respond to emerging trends in manufacturing.

Continuous improvement and adaptation ensure that digital transformation efforts drive innovation and operational excellence.

Summary

In summary, digital transformation is revolutionizing the manufacturing industry by integrating advanced technologies to optimize processes, enhance efficiency, and improve overall productivity. By adopting digital solutions, manufacturers can overcome traditional challenges, reduce costs, and ensure better quality control and safety.

Real-world examples demonstrate the practical benefits of digital transformation, while future trends indicate continuous innovation in smart manufacturing, MaaS, and AR/VR applications. Developing a successful digital transformation strategy requires aligning with business goals, selecting the right technology partners, and fostering a culture of continuous improvement. Embracing digital transformation is not just about staying competitive but also about leading the way in the next industrial revolution.

Frequently Asked Questions

This FAQ section addresses common queries about digital transformation in manufacturing, highlighting how manufacturing leaders can leverage the right tools and new technologies to improve efficiency, reduce maintenance costs, and enhance customer experience. By bridging the physical world with digital solutions, manufacturers can stay ahead in a competitive landscape while benefiting from reduced energy consumption and other benefits that drive business growth.

What is digital transformation in manufacturing?

Digital transformation in manufacturing is the strategic incorporation of digital technologies to enhance revenue, minimize costs, improve quality, and increase operational flexibility. This approach is essential for staying competitive in the evolving manufacturing landscape.

What are the key drivers for digital transformation in manufacturing?

The key drivers for digital transformation in manufacturing are the need for competitiveness, real-time data access, automation, AI, and the ability to adapt to changing market conditions. These factors are crucial for enhancing efficiency and meeting the demands of the modern industrial landscape.

How do digital technologies improve efficiency in manufacturing?

Digital technologies significantly enhance efficiency in manufacturing by streamlining processes, optimizing production schedules, and improving overall equipment effectiveness through smart manufacturing practices. These advancements lead to a more productive and responsive manufacturing environment.

What challenges do manufacturers face during digital transformation?

Manufacturers face significant challenges during digital transformation, including organizational silos, integration of legacy systems, and a shortage of skilled labor. These issues can hinder effective project management and overall progress in adopting new technologies.

How can manufacturers develop a successful digital transformation strategy?

Manufacturers can develop a successful digital transformation strategy by aligning their efforts with business goals, choosing appropriate technology partners, and cultivating a culture of continuous improvement. This approach ensures that digital initiatives effectively support overall objectives.